Unprecedented visibility

for hard-to-reach assets

Get real-time, actionable insights into the health of your critical industrial assets – even those in remote, inaccessible, or hazardous locations – along with predictive alerts that tell you exactly when and where maintenance is needed.

Unprecedented visibility

for hard-to-reach assets

Get real-time, actionable insights into the health of your critical industrial assets – even those in remote, inaccessible, or hazardous locations – along with predictive alerts that tell you exactly when and where maintenance is needed.

Trusted by leaders across industries

Maintaining hard-to-reach assets is a challenge. Samotics can help.

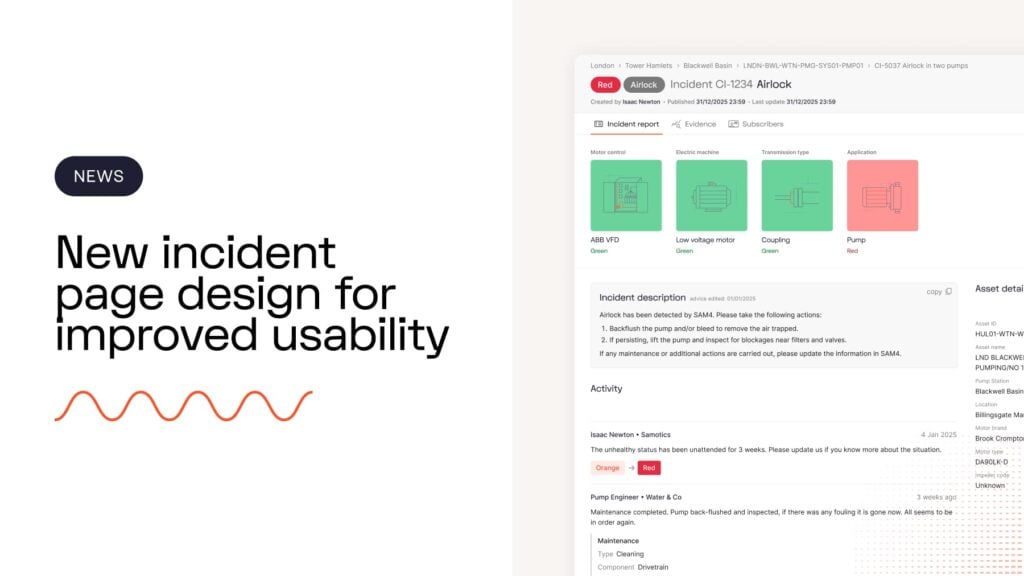

Using traditional techniques, equipment failures are often detected too late. Our AI-powered smart asset monitoring solution, SAM4, continuously monitors asset health, performance, and efficiency, helping you address issues before they escalate.

Safely monitor hard-to-reach assets

SAM4 uses Electrical Signature Analysis (ESA) to deliver insights from the motor control cabinet, giving you a detailed view of asset condition and performance without needing direct access to the asset.

Prevent failures and pollution events

Early detection of critical faults prevents equipment failures, disruptions, and costly pollution events. Our timely alerts help maintenance teams act quickly and keep your operation running smoothly.

Optimize energy use and prolong asset life

Energy waste impacts the environment and your bottom line. SAM4 identifies inefficiencies, helping you improve asset performance, avoid wear and tear, reduce costs, and lower your CO2 emissions.

Benefits of using SAM4

The leading technology for detecting failures in hard-to-reach assets

96% detection accuracy & fewer than 1% false alarms

Alerts and actionable insights sent straight to your inbox

Most customers see a return on their investment within months

Scalable technology and straightfoward to onboard

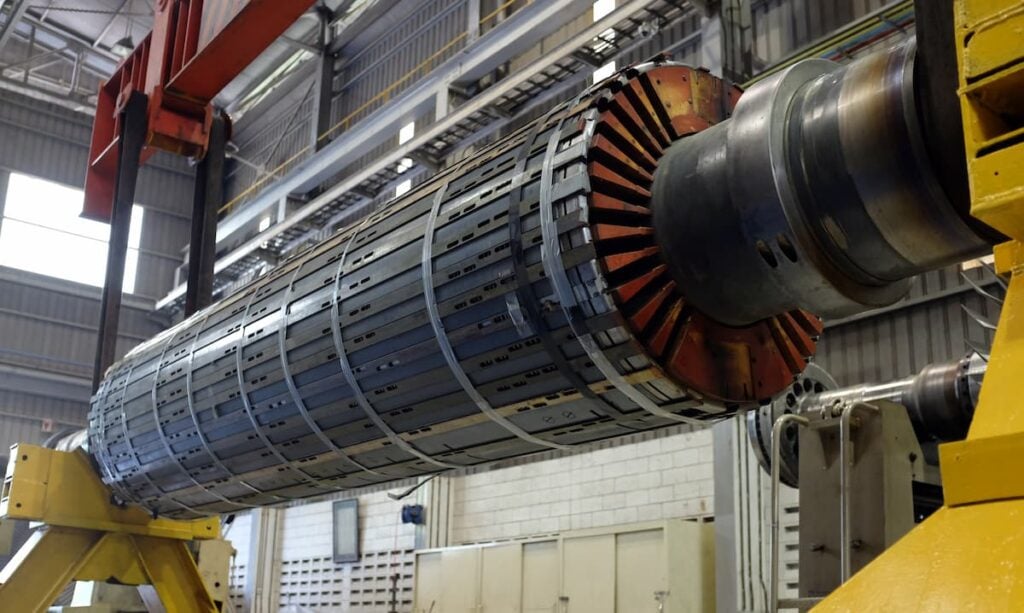

Equipment we monitor

Smart condition monitoring for pumps, motors, and more

Sewage pumps

Archimedes screw pumps

Mixers

Conveyor belts

Rotors

Fans

Testimonials

Delivering results across industries

Andy Roegis

Industrial Digitalization Manager

ArcelorMittal

Marcel den Blanken

Baggage Service Manager

Schiphol Airport

James Nobbs

Groundwater Engineering Manager, Water Services

Anglian Water

Austin Phillips

Operational Capex Implementation Manager

Southern Water